Ignite Possibility

Ignite Possibility

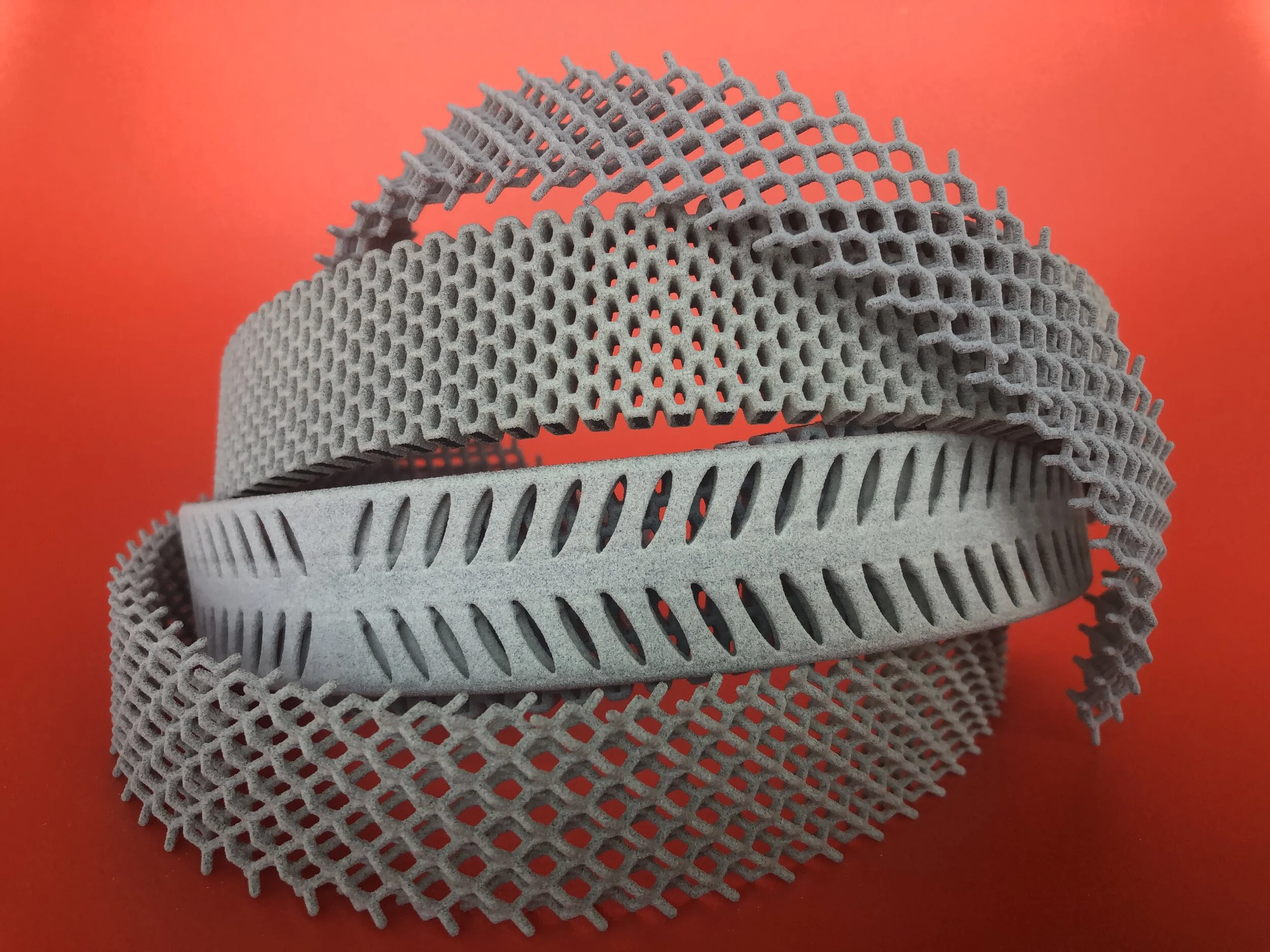

We believe that good design changes lives for the better. When developing the Quick-32r EEG headset with CGX, we created a design foundation on which we prioritized a simple operating scenario for the clinician and a gentle wearing experience for the patient. Using additive manufacturing for both prototyping and production made it possible to reduce part count and shorten the design cycle. The Quick-32r is used to increase understanding of diseases like PTSD and Epilepsy. How can we help you design meaningful change? Join us.

Learn More About the CGX Quick-32r

About the Cards

The CGX Quick-32r EEG Headset is featured on the third in a series of postcards created as a visual collection of our designs. Sent by mail, the cards celebrate Catalano Design’s most notable work over our more than 30 year history. Each card features a different project, unveiling an aspect of the design, story detail, or inspiration. Didn’t receive a card? Click the sign up button below and we’ll mail you the whole set.